Case Studies

FINAL INSTALLATION

Nest

The ancient technique of bronze casting is at least 6000 years old and very little has changed with today’s process. It is also known as investment casting using the lost wax, or direct burn-out method.

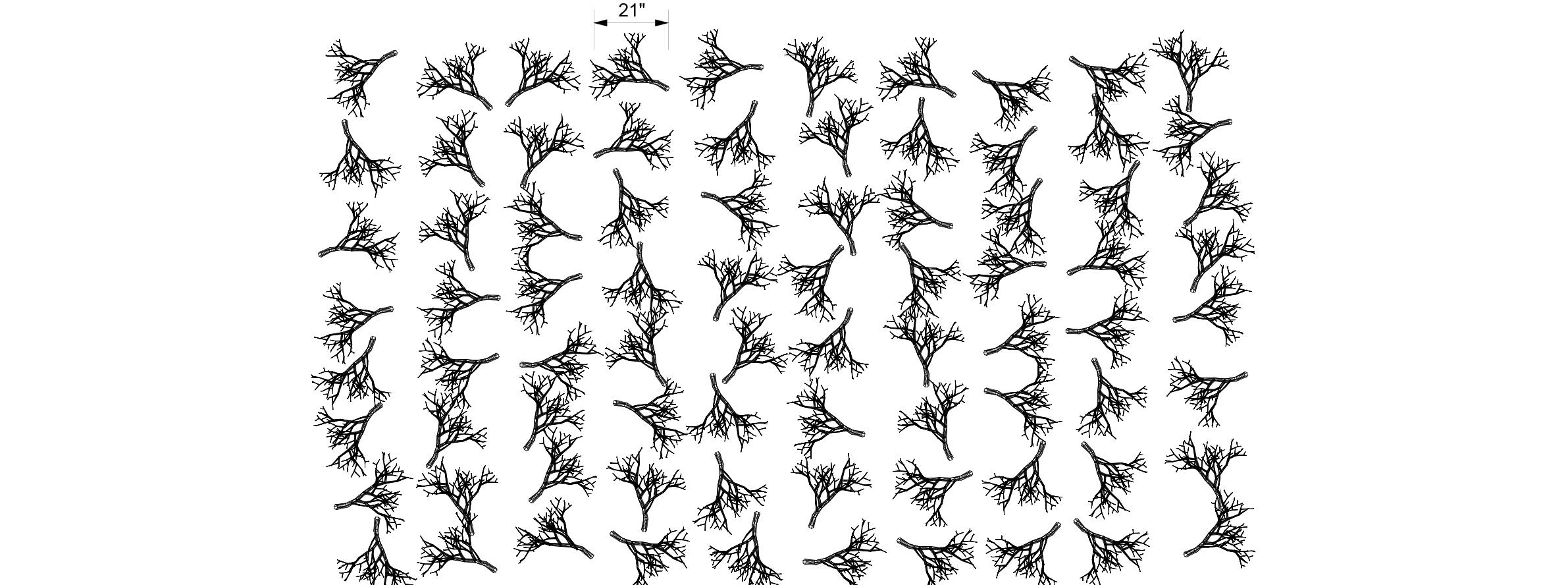

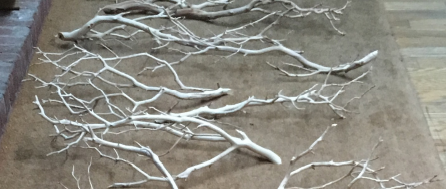

The process of creating a cast bronze nest, whether 6 inches across or 6 feet across begins with gathering the logs and branches that will make up the nest from the woods, beaches, pruning, etc. The logs and branches are numbered, photographed, catalogued and then delivered to the foundry to begin the investment mold process.

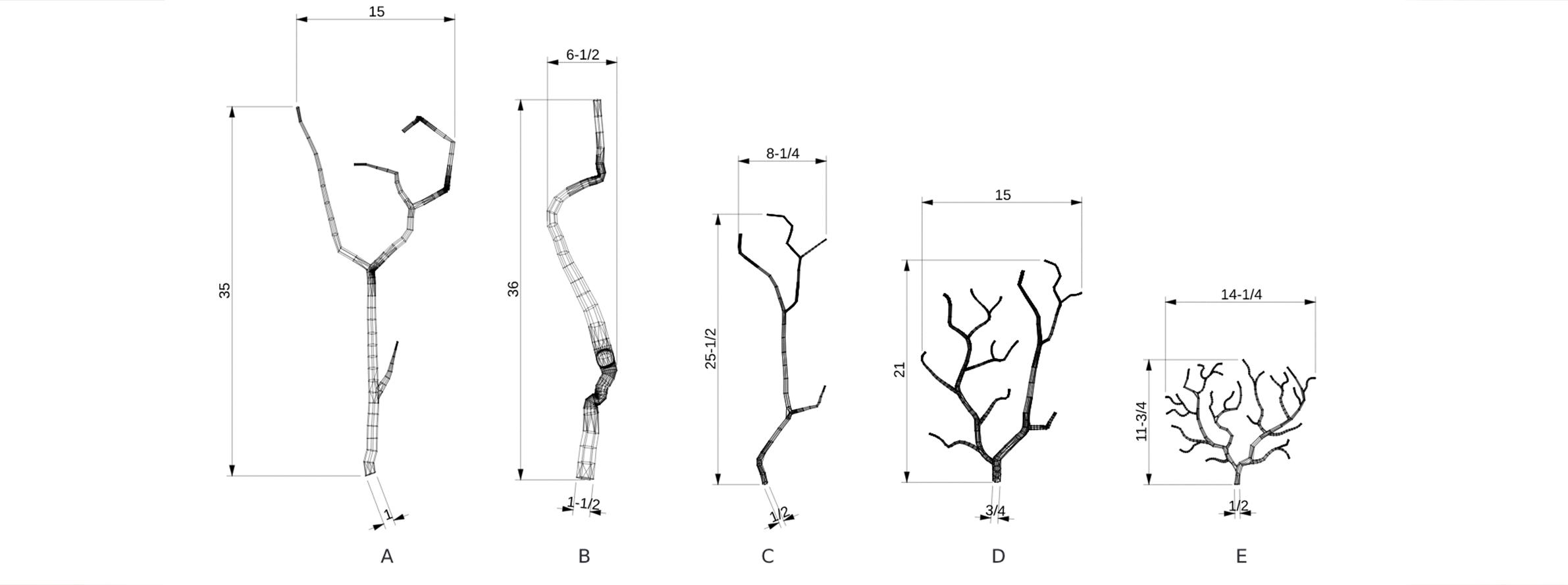

A gating system is engineered to provide channels through which the molten bronze will travel and fill once the piece is in the casting phase. This is done with a wax “sprue” that are attached to the log itself. The gating system is designed for efficient flow of molten bronze that allows gases to escape. Each log must have its own unique gating system.

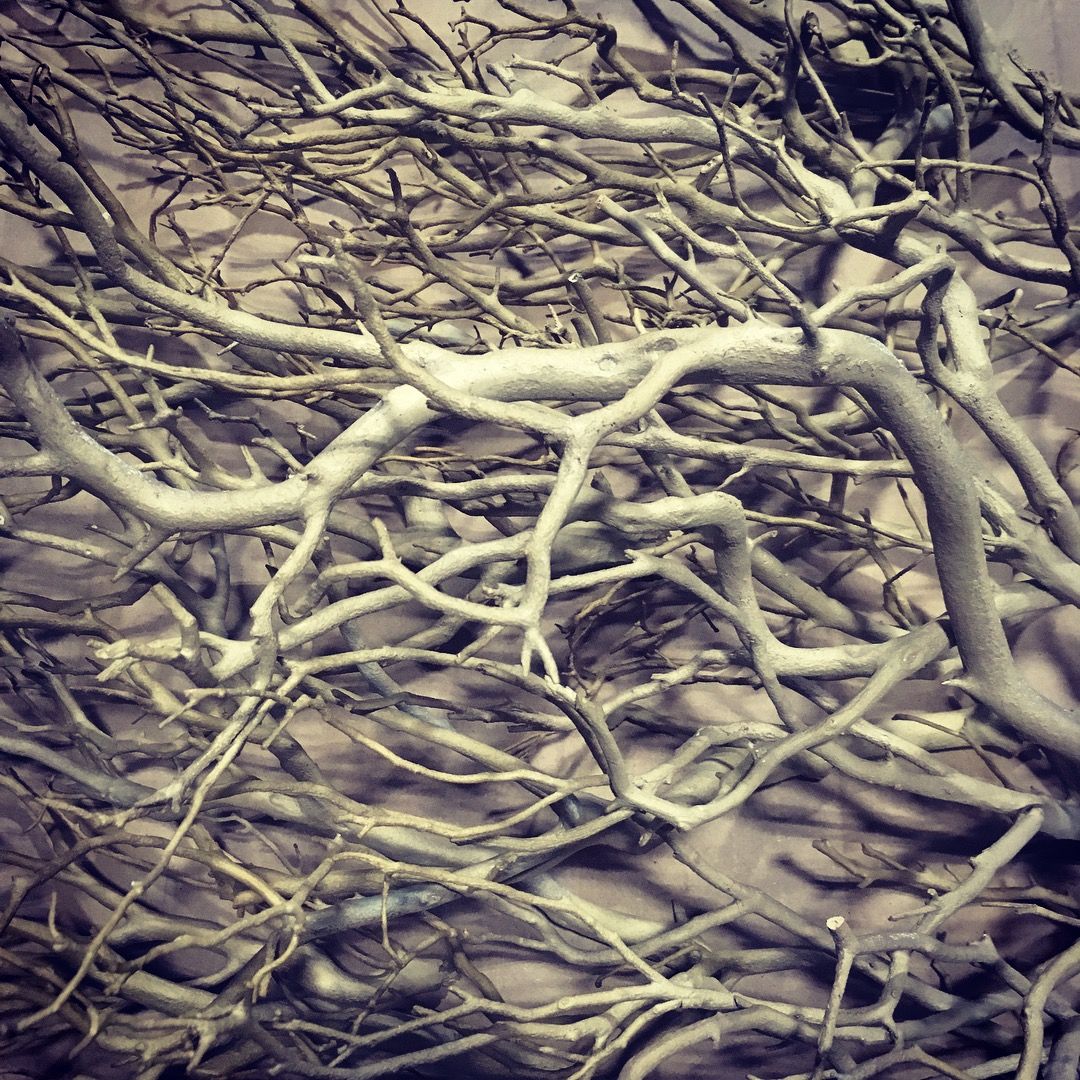

The gated wax “tree” is now invested in a ceramic shell. This is done by dipping the tree in a vat of ceramic slurry, then bathing it in silica sand. These steps are repeated 8-10 times, drying in between each layer, to encase the the wood and gates in a thick ceramic shell. This process can take as long as 3-6 weeks depending on drying time between layers.

Once the ceramic mold has dried and cured, it is fired in a kiln to hard ceramic. It is then placed in a burnout oven and heated to 2500 degrees to burn out the wood log and wax gating system. (this is where the term “lost wax” comes from as you “lose” whatever burnable item are inside). A hollow cavity now resides inside the shell where the log and gating system once were. These hollow cavities and channels will now act as arteries to carry the molten bronze to each section within the shell.

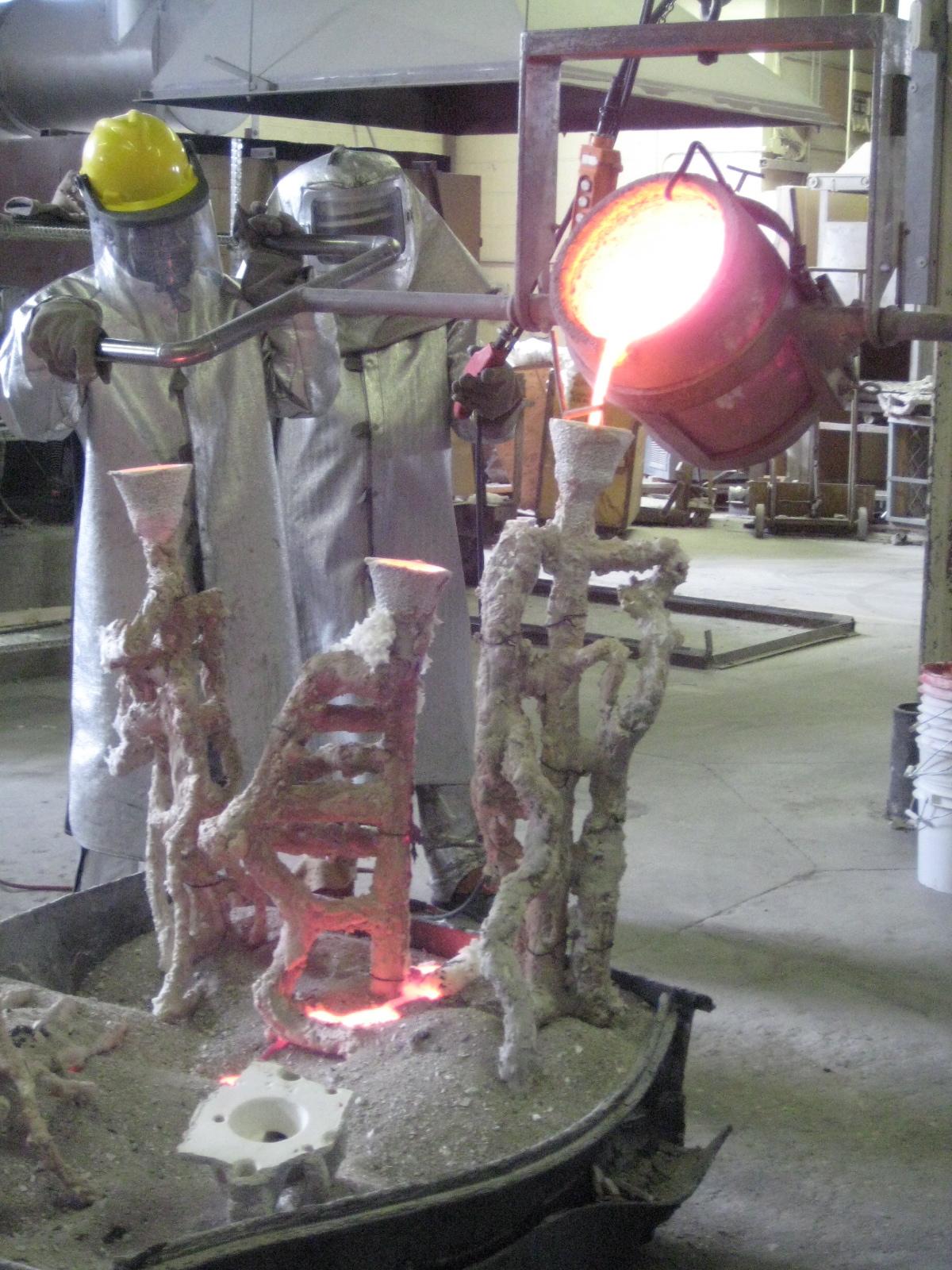

We use silicone bronze which consists mainly of copper, silicon and manganese. Before the pour, the ceramic shells are preheated to keep them from cracking when the molten bronze enters, while bricks of bronze are melted at over 2,000 degrees in a large ceramic crucible. Three artisans are generally involved in the pour. The “lead pour” directs the crucible to the awaiting shells while the “deadman” is responsible for maintaining its balance. The third member keeps the surface of the molten bronze clear of any impurities or slag. Team work amongst the three is essential for the safety and success of the pour.

The molds are left to cool before retrieving the castings. To retrieve the casting, the ceramic mold is broken away. Once the shell is removed, the engineered gates are cut and removed. The surface of the artwork is sandblasted, freeing the crevices from ceramic residue.

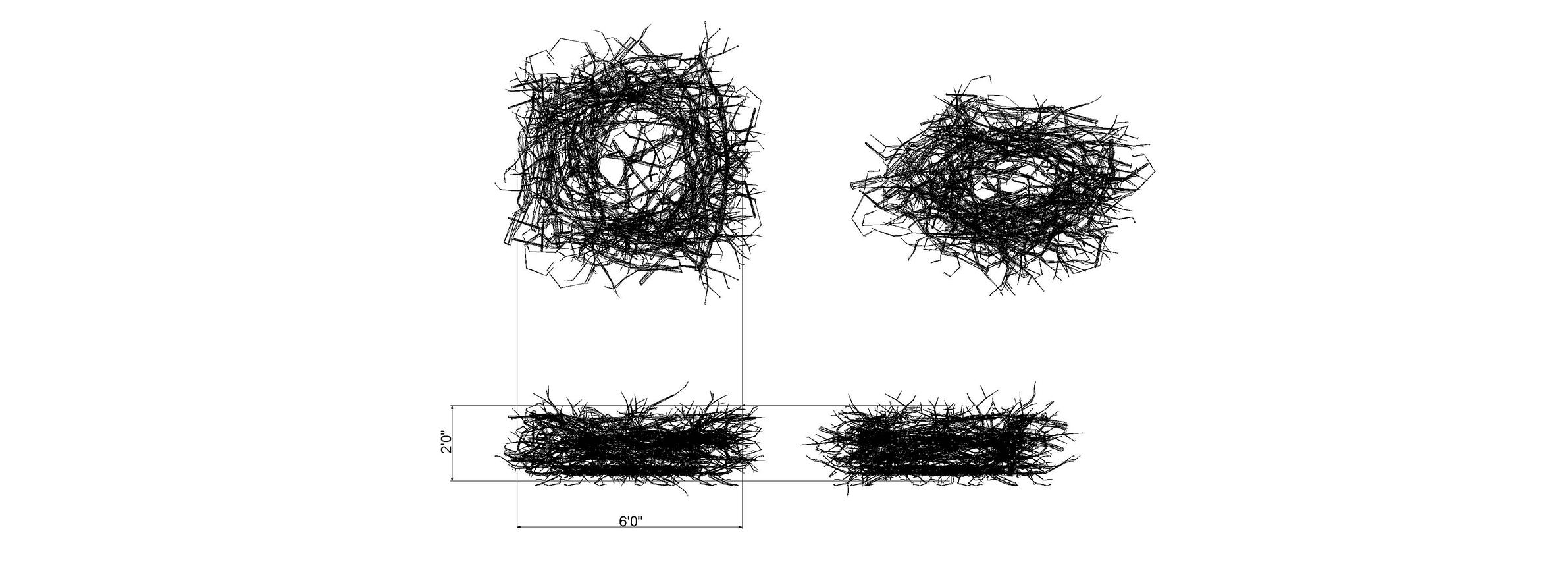

Once the bronze casting is out of the mold, the bronze must be chased and cleaned, ensuring that excess metal is ground off and any pits are filled. Surface texture is added back in where the gates were attached to blend with the rest of the log - this is called chasing. The branches and logs are essentially finished at this point and ready to be welded into the final sculpture with the many other logs and branches.

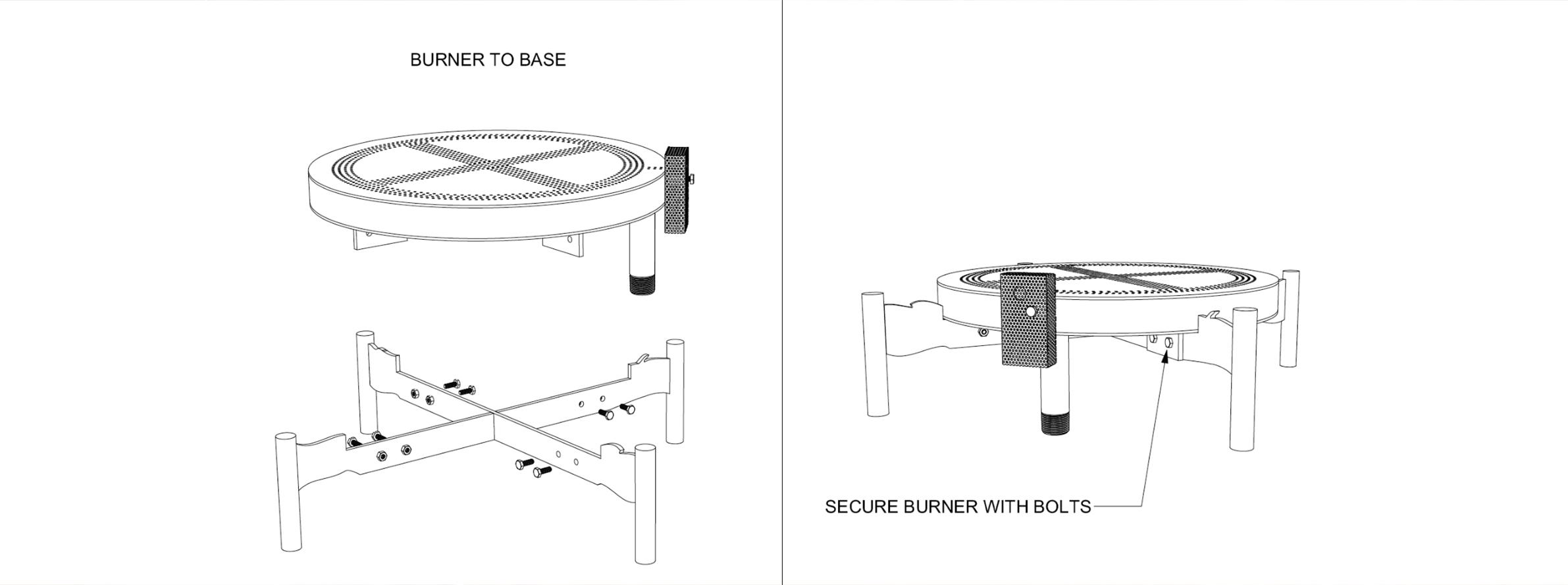

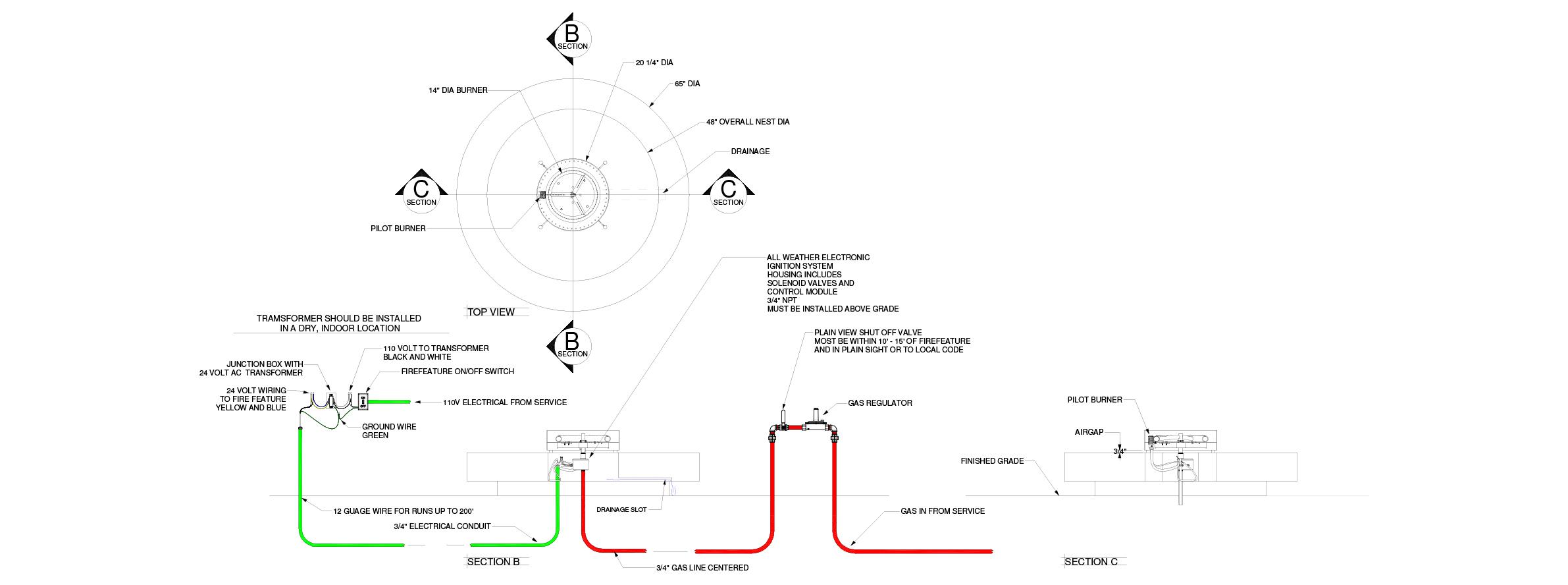

Once the nest assembly is complete, it is fitted with the gas burner and ignition system

DRAWING SETS

BRANCH COLLECTION, GATING & INVESTMENT MOLDS

BRONZE CASTING PROCESS

NEST ASSEMBLY